|

|

|

Source: OSHA.gov

Receiving and Storing

This section looks at how logs are unloaded and then stored within a

sawmill. Click on the following links for more specific information:

|

|

|

Hazard/Solutions:

Logs that are released improperly due to poor work practices may crush

workers.

- Release binders only from the side on which the unloader

operates, except when released by remote control devices or when the

person making the release is protected by racks or stanchions or the

equivalent.

1910.265(d)(1)(i)(c)

- Loads on which a binder is fouled by the unloading machine must have

an extra binder or metal band of equal strength placed around the load,

or the load must be secured so the fouled binder can be

safely removed.

1910.265(d)(1)(i)(d)

- The tripping mechanism that releases the stake or chocks must be on

the opposite side of the load being tripped.

1910.265(d)(1)(i)(a)

- Do not release binders on logs prior to securing with

unloading lines or other unloading devices.

1910.265(d)(1)(i)(b)

|

|

Worker releases load binders from

the side opposite the unloading side.

A powered industrial truck pushes

the load off the truck.

|

The following sequence of pictures depicts a safe unbinding and

unloading procedure:

|

The carrier truck approaches from the far side and places

carrier mechanism over load and secures it for the approaching

truck drivers. Note: The load binders are still secured in

place.

|

|

With the unloader holding the logs in place, the truck

driver releases the load binders.

|

After binders are released, the

driver moves to a safe

location.

|

|

Load is then removed from the

truck for storage in the log

yard.

|

|

|

|

|

|

Hazard/Solutions:

Loads could fall and strike or crush

workers

due to equipment failure.

- Machines used for hoisting, unloading, or lowering logs must be

equipped with brakes capable of controlling or holding the maximum load

in midair.

1910.265(d)(1)(ii)(a)

- The lifting cylinders of all hydraulically operated log handling

machines must be equipped with a device that prevents uncontrolled lowering of the load or forks in case of a failure in the

hydraulic system.

1910.265(d)(1)(ii)(b)

- A limit switch must be installed on powered log handling machines to

prevent the lift arms from traveling too far in the event the control

switch is not released in time.

1910.265(d)(1)(ii)(c)

- When forklift-type machines are used to load trailers, a means of

securing the loading attachment to the fork must be installed and used.

1910.265(d)(1)(ii)(d)

- A-frames and similar log unloading devices must provide safe clearance for swinging loads,

crotch lines and spreader bar devices. 1910.265(d)(1)(ii)(e)

- Log handling machines used to stack logs or lift loads above

operator's head must be equipped with adequate overhead protection. 1910.265(d)(1)(ii)(f)

- All mobile log handling machines must be equipped with headlights

and backup lights.

1910.265(d)(1)(ii)(g)

- Unloading devices must be equipped with a horn or other noise-making device.

1910.265(d)(1)(ii)(h)

- When the operator's vision is impaired or when operating in the

vicinity of other employees, coordinate the movement of unloading

equipment with audible or hand signals.

1910.265(d)(1)(ii)(i)

|

|

Tractor carrying logs through yard

in unstable manner

Unsafe handling of logs

Unsafe operation of loader in log yard

Log Carrier

Logs are in a stable, secure position

Knuckle boom unloading

logs from log truck

|

|

|

|

|

|

Hazard/Solutions:

Workers may be struck by

loads or equipment in unsafe log dumps, booms, ponds, or storage areas.

- Log dumps, booms, ponds, or storage areas used at night must be

illuminated in accordance with the requirements of American National

Standard A11.1-1965 (R-1970) Standard Practice for Industrial Lighting,

which is incorporated by reference as specified in Sec. 1910.6.

1910.265(d)(2)(i)(a)

- Log unloading areas must be arranged and maintained to provide a

safe working area.

1910.265(d)(2)(i)(b)

- Where skids are used, maintain a space adequate to clear a man's body

between the top of the skids and the ground.

1910.265(d)(2)(i)(c)

- Post signs prohibiting unauthorized foot or vehicle traffic in log

unloading and storage areas.

1910.265(d)(2)(i)(d)

|

|

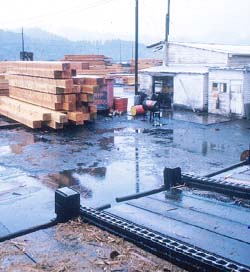

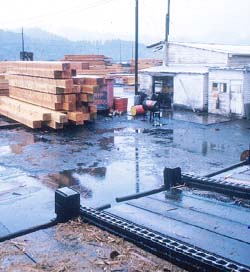

Unstable log pile creating an unsafe work area.

Logs in storage in log yard. Can you spot the

potential hazard?

Logs in log yard

Log yard - small sawmill

|

|

|

|

|

|

Hazard/Solutions:

Logs that are stored in an unsafe

manner could move or fall, then strike or crush workers.

- Dry deck storage areas must be kept orderly and maintained

in a condition that is conducive to safe operation of mobile equipment. 1910.265(d)(2)(v)(a)

- Logs must be stored in a safe and orderly manner, and roadways and

traffic lanes must be maintained at a width adequate for safe travel of

log handling equipment. 1910.265(d)(2)(v)(b)

- Logs must be arranged to minimize the chance of

accidentally rolling

from the deck.

1910.265(d)(2)(v)(c)

|

|

Knuckle boom loader at log deck

Secure, stable log piles in storage

yard

|

|

|

|

|

|

Hazard/Solutions:

Workers could be struck by

logs or crushed due to unsafe work practices.

- Safe access to the head rig must be provided.

1910.265(d)(3)(i)

- Log decks must be provided with adequate stops, chains, or

other safeguards to prevent logs from rolling down the deck onto the

carriage or its runway. 1910.265(d)(3)(ii)

- Erect a barricade to stop any log between the sawyer's stand and the log

deck. 1910.265(d)(3)(iii)

- Do not allow loose chains or other

equipment that may strike employees to hang over the log deck. 1910.265(d)(3)(iv)

Operator inside log carrier

|

|

|

Logs on log deck

Carrier truck moves logs onto log deck.

Log deck with end stops

|

|

|

|

|

|